Alan Poole* offers an insight into the important work by members of the Applied Petrography Group.

NB: This is a longer version of the article published in February's

Geoscientist.

Editor.

Geological materials are the fundamental components of all building construction. As such they are essential as dimension stone and aggregates and are also the essential raw materials for making bricks, tiles, cement mortar and concrete. They consequently are ubiquitous and essential for man-made structures of all kinds from garden walls to major bridges and dams.

Image left:

Image left: The raw materials for construction. Note the aggregate stockpiles in the foreground. Carboniferous Mudbank limestone Co. Clare, Ireland (Courtesy, J Kelly)

Members of the Society’s Applied Petrography Group provide the essential professional expertise to evaluate these materials. Architects and civil engineers will specify the types, quantities and qualities of materials to be used in a particular structure, and will specify the constructional requirements. Usually, an appropriate ‘expected design-life’ is also specified, which (for large dams or bridges) may be measured in hundreds of years.

The composition, characteristics and properties of these mineral materials are well understood by the petrographer. During the last 30 years the value of this expertise has gradually been recognised by architects and civil engineers. In the rare cases where premature deterioration of the structure has occurred, the causes - and remediation options - need to be addressed. Here too, a petrographer can quickly assess suitability for purpose of a natural geological material and offer alternative options to avoid costly building mistakes.

Applied Petrography Group

Some 15 years ago, the Engineering Group of the Geological Society, recognising the increasing numbers of professional geologists, petrographers and materials experts acting as advisors to the construction industry, instigated the Applied Petrography Group (APG) as one of its Working Parties. This has provided a forum for scientists of many disciplines and a platform for presenting research and case-study findings from both the UK and further afield to a global audience.

Some 15 years ago, the Engineering Group of the Geological Society, recognising the increasing numbers of professional geologists, petrographers and materials experts acting as advisors to the construction industry, instigated the Applied Petrography Group (APG) as one of its Working Parties. This has provided a forum for scientists of many disciplines and a platform for presenting research and case-study findings from both the UK and further afield to a global audience.

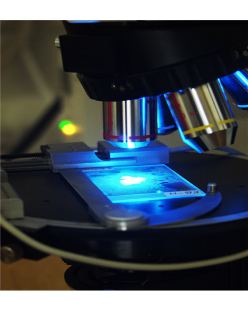

Image right: A thin section under test with UV illumination on an optical microscope stage (Courtesy A Bromley)

Membership of APG is still growing and now extends across Europe, with corresponding members from the Middle East, India, Canada and the USA. The work of APG members centres on the petrographic investigation of materials in the built environment, and consequently it includes representatives from civil engineering, a range of consultancy organisations, construction materials and cement manufacturers, academics, materials scientists and the quarrying industry. The Group also collaborates with other professional organisations such as the Institution of Civil Engineers and the Royal Microscopical Society.

Much of the work of the APG members is concerned with characterising and evaluating construction materials and forensic investigation into all kinds of materials failure. Its members work in many countries across the world, so information concerning overseas standards, environmental conditions, research findings and case studies are all of great value. Presentations on such wide-ranging matters are a feature of Group meetings.

Image left: Examples of poor quality (weathering grade 4) granite aggregate particles (left) and the same un-weathered aggregate (weathering grade 2) good quality (right).

Image left: Examples of poor quality (weathering grade 4) granite aggregate particles (left) and the same un-weathered aggregate (weathering grade 2) good quality (right).

The APG also aims to review and develop national and international standards, and is represented on British Standards committees dealing with aggregates, dimension stone and concrete. It has been instrumental in drafting the newly published standard BS 1881-211 which gives guidance on the petrographic investigation of hardened concrete and mortar. The Group is currently organising and implementing a European-wide inter-laboratory trial of optical fluorescence methods of the quantitative analysis of the water/cement ratio in hardened concrete.

In assisting the engineer, the professional petrographer will come to recognise the different particular and special properties required of rock materials in construction. These differences relate to such properties as durability, strength, permeability, chemical stability and composition (rather than the geological age and history, origin or stratigraphic position more familiar to the interests of the geologist). Consequently, although the graduate geologist will have the expertise to identify, characterise and evaluate these geological materials, the advice and information he or she provides must be enhanced to embrace the additional specialist knowledge of those properties that are appropriate for its intended use in a structure, and be able to present that information in a form relevant to the civil engineer.

Image right: The Val de la Mare Dam, Jersey. Note the bay on the left has been completely replaced, the reason is that it developed expansive cracking (below) due to a cement/aggregate reaction (AAR) in the concrete.

Image right: The Val de la Mare Dam, Jersey. Note the bay on the left has been completely replaced, the reason is that it developed expansive cracking (below) due to a cement/aggregate reaction (AAR) in the concrete.

This technical information ranges from the grading and particle shape characteristics of a sand or gravel to issues of durability, permeability, strength and stability. Petrographers have played a key role in helping national standards organisations worldwide to develop specification criteria and test procedures for determining the suitability of natural materials for a wide range of applications. In outline, the professional petrographer must be able to advise on:

- The location of sources of suitable materials and how to best access and process them

- The relevant standard specification and test requirements for each of the materials to be used in any particular structure

- The appropriate overall quality and durability of the materials that are proposed for a new structure

- The causes and extent of any deterioration in an existing structure, its identification and relevant remedial options

Image left: Cracking from the Val de la Mare Dam (above)

Image left: Cracking from the Val de la Mare Dam (above)

This specialist knowledge requires full understanding of standard specifications provided by national standards agencies and the interpretation of test results appropriate to the use of rock in a wide variety of civil engineering applications. Knowledge of the behaviour of composite materials like concrete, and an understanding of the various mechanisms of deterioration that may be encountered in buildings old and new, can present the petrographer with new and different intellectual challenges that often have substantial practical and financial implications.

The specialist knowledge of any professional petrographer working in construction alongside civil and materials engineers will include:

- Graduate-level understanding of petrology, petrography and geological processes;

- Specific knowledge of the required properties of constructional materials of all kinds;

- Specialised knowledge of the use of natural and composite materials in construction;

- Knowledge of national and international standard specifications appropriate to both the materials used and the structures themselves;

- Knowledge of a wide range of test procedures and the correct interpretation of their results;

- Knowledge of available investigative scientific techniques, their application and value;

- Scientific understanding of the causes and mechanisms of deterioration in buildings;

- General knowledge of legal requirements and procedures associated with arbitration and litigation.

Scientific understanding and research into constructional materials is worldwide in scope, so the importance of international collaboration cannot be overstated.

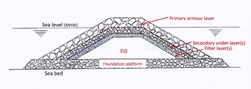

Image right: A schematic cross-section sketch of a typical conventional breakwater construction

Rock quality assessment

Rock quality assessment

A relatively straightforward materials study concerns the use of natural-rock armouring of the breakwater protection for a power-station water supply intake. The design of a seemingly simple rubble-mound breakwater is more complex than it might appear, because loose core material must not be allowed to wash out (‘pipe’) through gaps in the outer armour layers. Therefore, a series of graded underlayers is laid over the core material, while the outermost layer is constructed of blocks large enough to withstand movement and breakage during storm events.

Image left: Armoured rubble mound protection bunds to a power station water intake in the Middle East. Note rock piles marked, A are accepted while pile, D has been rejected.

Image left: Armoured rubble mound protection bunds to a power station water intake in the Middle East. Note rock piles marked, A are accepted while pile, D has been rejected.

Consequently block-shape, size, relative density and durability characteristics used are all specified, and are most stringent for the outer layer of armour. In this example, relative rock-density was specified to be greater than 2.5; primary armour blocks should be of equant shape and between 0.75 and 2 tonnes in weight. The source rock was a soft limestone.

On delivery to site some blocks were found to be unsuitable because of numerous joints and clay seams, which together with the high water absorption characteristics of the soft limestone (identified by petrography and confirmed by tests) would render them liable to rapid weathering degradation and breakage in storm events. Such blocks if used would compromise the design requirements of the structure.

Image right: Acceptable rock armour block.

Image right: Acceptable rock armour block.

Petrographic investigation of the clay seams revealed the presence of smectite clays. Standard testing for relative density and water absorption, joint frequency analysis, clay partings frequency and a drop-test breakage index, together allowed a rigorous distinction to be drawn between acceptable and unacceptable blocks. A series of examples of such blocks was placed on site to act as comparators for inspectors who then visually assessed the suitability (or otherwise) of the blocks as they were delivered.

Image left: Unacceptable block: note clay seams

Image left: Unacceptable block: note clay seams

Aggregates & concrete-cracking

Another illustration of petrographic investigation involving optical and scanning electron microscopy (SEM) concerns the use of aggregate in concrete. Unsuitable aggregates promote premature cracking and expansion of the hardened concrete as a result of ‘alkali-aggregate reaction’. This is a relatively rare - but very costly - form of deterioration, and much research has been aimed at understanding the mechanisms involved, and designing measures to avoid it.

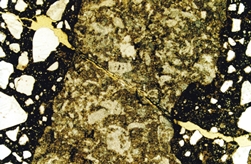

In outline, some poorly crystalline forms of silica, opal being the best known, will react with alkalis, usually from the cement used, to form an alkali-silica gel. This absorbs water, swelling with sufficient force to crack the concrete in which it occurs. Often only a small percentage of reactive aggregate is involved. It is the petrographer’s job to identify this reactive mineral component within an otherwise satisfactory aggregate. Detailed examination of petrographic thin sections will identify which aggregate particles are the seat of the reaction. Further investigations using SEM with X-ray microanalysis will show the composition of the gel and the siliceous component responsible.

Image right: Map cracking due to AAR on a concrete pumping plant wall, Tai Po, China

Cracks resulting from such expansive reactions can lead to a variety of possible damage features including:

Cracks resulting from such expansive reactions can lead to a variety of possible damage features including:

- Loss of strength, particularly at critical points in a concrete structure

- Misalignment between elements of a structure as in the Val de la Mare Dam

- Leakage through water-retaining structures

- Ingress of air and water into the concrete, allowing other deleterious mechanisms (such as corrosion of steel reinforcement) to initiate.

Image left: A thin section of concrete in plane polarised light showing a coarse aggregate particle traversed by an open crack (yellow) partially infilled with alkali-silica gel (now dehydrated).

Image left: A thin section of concrete in plane polarised light showing a coarse aggregate particle traversed by an open crack (yellow) partially infilled with alkali-silica gel (now dehydrated).

Since the reaction occurs between some aggregate components and the alkalis that are always present in the pore-fluids even of hardened concrete, it is very difficult to arrest - and it will typically continue slowly for many years. Remediation and repair of affected structures is both difficult and costly. In some minor cases this has led to the long-term monitoring of affected structures (to keep a check on structural integrity) while in some cases it has led to demolition and replacement. However, most countries have now implemented specifications for avoiding potentially reactive aggregates, and have imposed strict limits on the alkali content of the cements used in all new concrete structures.

Carcinogenic minerals

Image right: A general view of the disused quarry faces

Image right: A general view of the disused quarry faces

The redevelopment of a disused quarry, and the petrographic analysis it set in train, provides an illustration of a quite different type of investigation. It also indicates an aspect common to many investigation briefs as presented to the petrographer. In this illustration, although the client’s overall objective had been the redevelopment of a quarry site, and was primarily concerned about the jointing and vein-infilling in the rock, the type of redevelopment envisaged was not clarified. Therefore, the petrographic investigation focused on the nature of the rock materials, the jointing and vein infillings in the exposed faces, in the residual stockpiles and in the hard-standing working areas adjacent to the quarry itself.

The quarry concerned was situated in South West England and was developed in basic volcanic dolerites of early Triassic age. Because SW England did not suffer glaciation, the deep geological weathering profile developed in these volcanic rocks through the Tertiary had not been significantly stripped from exposed surfaces. However, tectonic movements had produced significant jointing - some with slickensided surfaces within shear zones, and late-stage silica-rich mineralisation.

Image left: Severe jointing in several orientations typical of the lower quarry face

Image left: Severe jointing in several orientations typical of the lower quarry face

On-site inspection of the old quarry confirmed that the three main benches were stable, but the lowest bench was submerged under water. The largest exposed bench was eight metres high and the one above 3.5m high - with an overburden of approximately two to three metres. It was clear from field inspection (confirmed by visual and microscopical investigation of samples in the laboratory) that the upper bench was of highly weathered dolerites (weathering grade IV), while the lower bench was of fresher rock (weathering grades I and II - BS5930, 2015). Weathering grades of I and II are suitable as aggregate for concrete and general construction. Rock of weathering grade IV would only be of use as general fill material.

Joints and veins were obvious in many quarry faces, with four or more principal joint directions. Careful inspection of a number of infilled joints and shear-planes confirmed that the infillings were principally of quartz; though epidote, chlorite, calcite and a fibrous asbestiform material were also present. The fibrous material was identified as an asbestos mineral. Altogether, 15 samples of rock and vein material were collected for laboratory examination. The asbestos material was examined in greater detail using polarising light microscopy and dispersion staining techniques. Nine samples were found to contain asbestos. One was of anthophyllite, the remainder were identified as actinolite.

Image right: Examples of an exceptionally thick (40mm) fibrous vein infill

The presence of asbestos would likely prove be a problem for any kind of redevelopment in this quarry site. In spite of having been successfully worked for aggregate in the past, and although actinolite and anthophyllite are not considered as carcinogenic as crocidolite (blue asbestos), UK regulations require that all cement – asbestos containing products have been banned since 1999. Today, working materials containing asbestos will have health and safety implications for workers (Health and Safety Executive 2005).

Conclusions

The three examples show but a small part of the range and variety of investigative work undertaken by APG members. In many cases the investigations are more complex, involving specialist electron microscopy, chemical analysis and X-ray methods, as well as optical petrography. However, many of these more interesting studies have significant financial and legal implications and consequently remain confidential.

The extensive variety of investigation undertaken by professional petrographers provides great interest and challenge to those working in this expanding field. Whether they work as individuals, in small groups or in larger companies, APG members find they are very busy and have more work than can be easily managed! The principal problem seems to be one of recruiting graduates with the appropriate skills and flexibility to be able to deal with this variety and range of investigations coming from all over the globe on an almost daily basis.

Author

* Alan Poole followed an academic research and teaching career in the University of London until 2000. In the last 30 years he specialised in problems associated with concrete and related materials, producing over 120 scientific papers. He wrote chapters on materials for a number of technical books including the Geological Society’s SP9 and SP16, is a co-author of ‘Concrete Petrography’ (2016), and co-editor of ‘Alkali-aggregate reaction in concrete, a world review’ (2017) He is secretary to the Geological Society Engineering Group’s ‘Applied Petrography Group’ (APG) and has been a member of British Standards Institution committees concerned with concretes and aggregates.

Contact E: [email protected]. If you are interested in joining the APG, visit https://www.geolsoc.org.uk/Groups-and-Networks/Specialist-Groups/Engineering-Group/Working-Parties/Applied-Petrography-Group or W: www.appliedpetrographygroup.com

Further Reading

- BS 1881- 211, 2016: Testing concrete – Part 3: Procedure and terminology for the petrographic examination of hardened concrete. London, BSI Global.

- BS 5930 2015: Code of practice for site investigation. London, BSI Global.

- BS 812 – 2 (1995). Testing methods. Methods of determining density. BSI Global

- CIRIA & CUR 1991: Manual on the use of rock in coastal and shoreline engineering. CIRIA Special Publication 83, CUR Report 154.

- Geological Society 1993: Aggregates. Sand, gravel and crushed rock aggregates for construction purposes (2nd Edition) Eds. Smith, M R & Collis, L Geological Society Special Publication SP009.

- Geological Society 1999: Stone: building stone, rock fill and armourstone in construction. Ed. Smith, M R. Geological Society Special Publication SP 016.

- Health & Safety Executive. 2005. Asbestos: The analysts’ guide for sampling, analysis and clearance procedures. HGS 248, HSE Books (available as a free download from HSE website)

- Ingham, J P 2011: Geomaterials under the microscope - a colour guide. Manson Publishing Ltd.

- Poole, A B & Sims, I 2016: Concrete Petrography - a handbook of investigative techniques. Taylor and Francis, CRC Press.

- Sims, I & Poole, A B 2017: Alkali-aggregate reaction in concrete - a world review. Taylor and Francis, CRC Press.