Many UK towns were built on coal. Charlotte Adams, Alison Monaghan and Jon Gluyas highlight the vast potential to repurpose our abandoned mining infrastructure as a low-carbon heat source

Adams, C., Monaghanand, A. & Gluyas, J., Mining for heat.

Geoscientist 29 (4), 10-15, 2019

Deep coal mining in the UK has left a legacy of flooded former mines. Water within these mines can provide a source of heat energy. Durham University is researching the potential of this resource and the British Geological Survey (BGS), commissioned by the Natural Environment Research Council (NERC), are constructing and operating a research site in Glasgow to further understanding of mine energy systems.

When coal was king

Over the past century, vast quantities of coal were mined from the UK subsurface as it fuelled our industrial and economic growth. The 15 billion tonnes mined are equivalent to a 5-cm-deep layer of coal spread over the entire UK land surface. Despite the wealth generated by the UK’s coal deposits, coal is now regarded as a “dirty” fuel because of the associated CO

2 and other pollutant emissions, and is being phased out of our energy mix. UK government demonstrated its commitment to reducing coal use by joining 27 other national governments that have signed up to the “powering past coal alliance” and there are now days when coal is not being burned to produce electricity in the UK.

The UK has made good progress in decarbonising its electricity supplies over the past decade, with around half of UK electricity demand supplied from low-carbon sources (DBEIS, 2018). However, electricity provision is only part of the story and half of the UK’s total energy demand is used to produce heat, most of which is consumed by the domestic sector. Heat is predominantly produced from burning natural gas. In the meantime, the UK has been a net importer of natural gas for over a decade and is reliant on other nations to meet any shortfalls in demand.

Developing a legacy

Our abandoned mining infrastructure now lies largely derelict and many have forgotten its existence. Yet, people in former mining towns and villages remain strongly connected to their mining heritage, even though its decline brought hardship and, in some areas, environmental pollution.

Our mining legacy and the associated infrastructure could be repurposed and has potential as a future energy source. The mine shafts and galleries that are now flooded contain copious volumes of water at 12-20℃. Clearly you would not want to take a bath in water of this temperature, but heat pumps can boost temperatures to provide hot water and space heating. Heat pumps require an energy input, but because each kW of electrical energy input could be expected to deliver a heat output of 3-4 kW, heat is provided in an energy-efficient way.

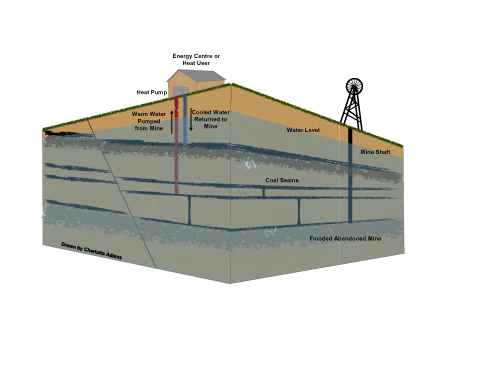

Mine water is accessed by drilling boreholes into flooded workings through which water is abstracted, heat is removed and the temperature boosted with a heat pump, before the water is returned to the subsurface (Fig. 1). Using mine water as an energy source compared with individual closed-loop, ground-source heat pumps offers some advantages for domestic properties. Decreased garden size of newer housing stock leads to reduced space for horizontal ground arrays, meaning that boreholes would be required, which are more capital intensive. Mine-water heat systems are generally operated open-loop, which offers better thermal efficiency than standard closed-loop ground-source heat systems. Finally, mine-water systems offer economies of scale, meaning that clusters of hundreds of properties could be served from a single mine and a few boreholes. To deliver this vision requires changes to planning and building control policies that support the future development of low-temperature energy systems.

Figure 1, Schematic Diagram of a mine water heat pump system (Drawn by Charlotte Adams)

Figure 1, Schematic Diagram of a mine water heat pump system (Drawn by Charlotte Adams)

Durham Energy Institute at Durham University is undertaking national, regional and local assessments of mine energy potential for a range of applications, under the auspices of BritGeothermal, which is a national research partnership for deep geothermal energy. This work includes assessing domestic residences, industrial developments and municipal buildings for mine energy systems.

For these assessments, we need to understand the nature of the subsurface infrastructure and appreciate how water quality can evolve, both during mine abandonment and following periods of abstraction. Research shows that following long periods of abandonment, water within mines can become highly stratified, with better-quality water generally lying above poorer-quality water (Nuttall & Younger,

J. Contam. Hydrol. 2004). Pumping and abstracting water from mines induces turbulence and mixing within the mine. This means that the eventual quality might be poorer than expected and it is important to take samples of the entire water column if possible. Water quality may change with pumping rate and is linked to the areas of workings being drawn from. Quality may improve once a few shaft volumes have been pumped.

Many mine waters contain iron, which is a remnant of the interaction between the oxygenated mine-water and pyrite within the coal (particularly high-sulphur coals) and is the nemesis of mine-water management. As long as air is excluded from a mine-water heat pump system, iron remains in solution, but introducing air even when there are low concentrations of iron present (1mg/l) leads to the deposition of ochre. Though iron ochre precipitation is key for mine-water treatment, in a heat-exchange system this can cause severe clogging and fouling of system components. Ochre precipitation is normally avoided by keeping systems under positive pressure, limiting dissolution of oxygen.

To assess the potential of this resource, it is necessary to obtain from the UK Coal Authority the abandonment plans for seams within the collieries worked, and then use these to calculate the worked areas and seam thickness. The large-scale extraction of coal from the subsurface leaves voids that remain long after mine abandonment. Yet, these voids will not remain exactly as they were at abandonment. Shafts were often filled with rubble from the demolished topside colliery infrastructure before being capped, rendering many of no value for future water pumping. The floor of galleries may heave and roof material may collapse, leading to tunnels with partial blockages along their length.

The amount of remnant void space depends upon the method of deep mining employed. Early ‘room-and-pillar’ mining involves working a grid, leaving pillars of coal intact for roof support and mining the areas between (Fig. 2). Room-and-pillar mining was later replaced by longwall mining (first developed in Shropshire in the 17th Century), a more efficient means of removing coal that involves driving tunnels to the farthest extent of the mine, then removing coal from the seam laterally whilst retreating from the workings. Many areas formerly mined by the room-and-pillar method were latterly reworked using longwall extraction. As longwall mining proceeds the overburden above the seam subsides producing “goaf” (collapsed waste). Consequently, an area mined by room-and-pillar methods can be assumed to have around 50% of the original void space remaining and, for longwall mining, around 20% of the original void space remains (Younger & Adams, Tech. Report 1999). These voids, in effect, have created an anthropogenically-enhanced aquifer in which heat can be extracted from or reinjected into the large water volumes existing within the mine workings.

Figure 2, Stoop-and-room (Scottish terminology for pillar-and-room) mine workings subsequently exposed by opencast coal workings at Blindwells, Scotland. Photo number P001520 BGS©UKRI. The image illustrates the connected void space (‘rooms’) that could be targeted for mine water geothermal projects

Figure 2, Stoop-and-room (Scottish terminology for pillar-and-room) mine workings subsequently exposed by opencast coal workings at Blindwells, Scotland. Photo number P001520 BGS©UKRI. The image illustrates the connected void space (‘rooms’) that could be targeted for mine water geothermal projects

The potential for the flooded abandoned collieries of the UK to provide a source of heating, cooling and energy storage is huge. The UK Coal Authority estimates that abandoned flooded mines contain around 2.2 million GWh of heat, with an even greater potential for heat storage. Furthermore, because coal spawned the development of many of our towns and cities, mine energy resource aligns well with centres of heat demand. The Coal Authority estimates that around one quarter of UK housing stock overlies areas of abandoned mine workings.

There are a few examples of mine energy projects that serve smaller and individual developments in the UK. Bridgend Council in Wales is working to deliver a larger district heating system that will initially supply heat to around 150 homes. At Heerlen in the Netherlands, abandoned mines are used effectively to deliver space heating and cooling to around 200,000 m

2 of mixed use new and retrofit buildings via a 7-km-long heat network (Verhoeven et al.,

Energy Procedia 2014). In addition to delivering low-carbon energy to Heerlen, the money spent on heat by their customers is retained within the region rather than going to a major, national energy supplier, thereby promoting economic regeneration to a formerly deprived mining region.

Hostages to fortune

The UK geothermal industry has struggled to develop, not from lack of potential but because of the upfront capital cost and risks involved with drilling boreholes that are not guaranteed to flow adequate quantities of water for energy extraction. There is only one operational deep geothermal heat scheme in the UK, at Southampton. It was developed in response to a national audit of the UK’s geothermal resources in the 1980s, prompted by the oil crisis.

Although abandoned mines are shallower and the temperature of water within them is cooler, copious quantities of water flow through these systems, thus reducing development risk. The UK is sitting above an extensive but yet-to-be commissioned heat network. Mine energy has a much higher technology readiness level than other low-carbon replacements for natural gas, such as hydrogen. Heat-pump technology is proven, we have a long experience of drilling in mining areas and have evidence of success, as demonstrated by projects in the UK and beyond. Why then is this type of heat not used more widely? A whole new approach to the licensing of heat, risk-averse attitudes to “untested technologies” (Banks,

GSL SP 2004) and the fact the UK has had ready access to relatively cheap gas supplies provide some answers. Complexities associated with retrofit of heat exchangers and heat pumps, economic risks linked to difficulties in securing long-term contracts for heat supply and system maintenance, as well as concerns over water quality and subsidence may present barriers to widespread development.

BritGeothermal is lobbying for changes to national planning policy, licensing and regulation of subsurface use to ensure that mine energy potential is considered when planning new developments. This group is also investigating the mine energy potential of a number of former coalfields and it is hoped that the new Glasgow Geothermal Energy Research Field Site (BGS, 2018), as well as a variety of industrial and council supported projects in north-east England, will significantly reduce subsurface, geoscientific uncertainties and risks, raise awareness and stimulate the market for this low-carbon energy source.

UK Geoenergy Observatories

The BGS is constructing and operating the UK Geoenergy Observatories on behalf of NERC. This is an ambitious £31 million investment that will develop and operate two subsurface research observatories. Funded by the UK Government Department for Business, Energy and Industrial Strategy (DBEIS), the observatories will facilitate improved understanding of subsurface change beneath our feet.

The Glasgow Geoenergy Observatory, currently being constructed, will focus on shallow, low-temperature mine energy opportunities using the flooded abandoned mine workings below the east end of the city. The other UK Geoenergy Observatory, in the Ince Marshes area of north Cheshire, will focus on improved understanding of the subsurface environment across a 12 km

2 area, down to 1,200 m below ground. This knowledge can be applied to a range of energy technologies.

Site geology

The Glasgow Geothermal Energy Research Field Site is located on the western side of the Central Coalfield of the Midland Valley of Scotland, within glacial and post-glacial Quaternary superficial deposits, overlain by a variable thickness of made (anthropogenic) ground. The Quaternary deposits vary in thickness up to 30 m. The upper surface of bedrock was incised, with thicker accumulations of superficial deposits infilling a broadly NW-SE trending channel following the modern-day River Clyde. There is widespread made, filled and landscaped ground relating to a variety of prior industrial land use, in some places this is 10 to 15 m thick.

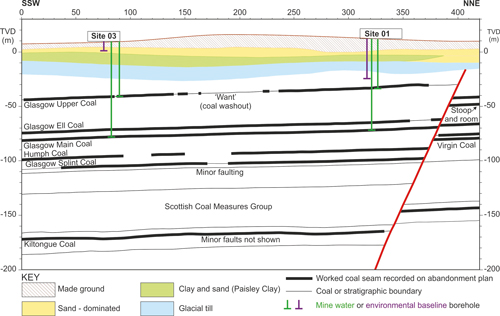

These deposits rest on approximately 300 m of bedrock strata of the Scottish Upper, Middle and Lower Coal Measures formation—cyclical sedimentary rocks of sandstone, siltstone, mudstone and coal. Recorded coal mine workings in the area were active from 1810 to 1934, with total extraction and stoop-and-room workings shown on abandonment plans. It is expected that total extraction areas collapsed within a few years of mining to form goaf and that the mines will be flooded. As the cross-section in figure 3 shows, there are multiple levels of mine workings in the area where the Glasgow research site will be situated.

Figure 3, Cross-section of the geology in the Cuningar Loop area with the planned borehole target depths shown, UK Geoenergy Observatory in Glasgow. Note that the thick black lines represent areas recorded on abandonment plans as mine workings. TVD=true vertical depth relative to Ordnance Datum, top X-axis is in metres.

Figure 3, Cross-section of the geology in the Cuningar Loop area with the planned borehole target depths shown, UK Geoenergy Observatory in Glasgow. Note that the thick black lines represent areas recorded on abandonment plans as mine workings. TVD=true vertical depth relative to Ordnance Datum, top X-axis is in metres.

Glasgow site aims

The Glasgow Geothermal Energy Research Field Site aims to provide access to infrastructure and a wide range of openly accessible data to answer key research questions on low-carbon, mine energy systems, to enable sustainable, responsible and more widespread use of this resource. This facility will develop understanding of factors critical to successful development of mine energy systems, such as the longevity and sustainability of the resource and the hydrogeochemistry of the mine water through time. Development of the field site will also explore the risks associated with drilling into the roadways, pillars and goaf at different depths within abandoned mines. It will also explore the potential for subsurface connections to exist between near-surface and mine waters, and the consequences of this for environmental protection.

The infrastructure to be installed will include an array of 12 boreholes at various depths equipped to provide a continuous time-series of geological, hydrogeological and thermal datasets (Fig. 3). Samples, tests and measurements will be taken from the boreholes, such as temperature and aquifer properties, water chemistry and microorganisms (geomicrobiology). Environmental monitoring of near-surface soil chemistry, soil gases, seismicity, surface and groundwaters will also be undertaken prior to development, to provide a site baseline before any geothermal research takes place. Existing, commercially developed mine energy systems focus on heat production and there is limited subsurface and environmental monitoring data. In contrast, the Glasgow research site offers huge potential for researchers to access large, integrated datasets on the mine-water system. It will also provide opportunities for researchers to undertake their own experiments, with the common aim of reducing uncertainty on mine energy systems and environmental impacts for schemes across the UK and beyond.

The infrastructure

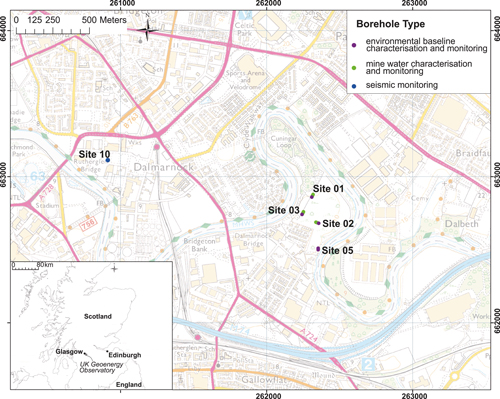

Planning approval and permits for the characterisation and monitoring phase have been granted, with the majority of the boreholes located at the Cuningar Loop, Rutherglen (Fig. 4). Planned drill lengths are between 10 and 90 m. Six mine-water boreholes target the Glasgow Upper and Glasgow Main coal workings (Figs 3, 4). Five boreholes will help characterise and monitor the environmental baseline by targeting the upper bedrock and the superficial deposits. A range of sensors such as resistivity and temperature cables and groundwater data loggers will be installed. Regular water samples will also be taken for geochemical analysis. In addition, there is one seismic monitoring borehole of around 200 m drill length at Dalmarnock (Fig. 4), which has recently delivered a borehole core. A new core-scanning facility at BGS Keyworth will be used to give a high-resolution geophysical, mineralogical, geochemical and optical/X-ray downcore record (see BGS 2018 for more detail).

Figure 4, Map of the UK Geoenergy Observatories: Glasgow borehole locations. Contains Ordnance Survey data © Crown copyright and database rights. All rights reserved [2019] Ordnance Survey [100021290 EUL].

Figure 4, Map of the UK Geoenergy Observatories: Glasgow borehole locations. Contains Ordnance Survey data © Crown copyright and database rights. All rights reserved [2019] Ordnance Survey [100021290 EUL].

Timescale and research access

Drilling of the first phase of boreholes started in November 2018, with construction and testing expected to take a year or so. Subsequent to that and permissions for the installation of the heat pumps and above-ground infrastructure that will allow geothermal research, the research site will be open to the whole of the UK science community to undertake research, for a 15-year lifespan.

In 2019, the continuous data from the boreholes will be available and freely accessible to the public, government, regulators, academia, and industry via an online portal. Rock and fluid sample material will also be available for research and there will be limited early access to the observatory, including training opportunities for students to observe borehole drilling and sampling.

Securing a future energy source

The high-resolution datasets from Glasgow’s subsurface will provide a step change in understanding of low-temperature heat resources, balanced with their impacts on people and the subsurface to surface environment. Clearly the potential to develop our mining heritage as a future energy source is huge. The message that our abandoned mining infrastructure, which was so hard won, could provide a source of low-carbon energy for the future is a powerful one.

Charlotte Adams, Durham University and BritGeothermal research Partnership www.britgeothermal.org; [email protected]

Alison Monaghan, BGS; [email protected]

Jon Gluyas, Durham University and BritGeothermal research Partnership

Further reading

Banks, D. et al. (2004) Heat pumps as a tool for energy recovery from mining wastes. Geological Society, London, SP 236, 499-513.

BritGeothermal: http://www.britgeothermal.org

British Geological Survey (2018) Glasgow Geothermal Energy Research Field Site;

http://www.bgs.ac.uk/research/energy/esios/glasgow/home.html

Department for Business, Energy and Industrial Strategy (DBEIS) (2017) Energy Consumption in the UK 2018 Update;

https://www.gov.uk/government/statistics/energy-consumption-in-the-uk

Nuttall, C.A. & Younger, P.L. (2004) Hydrochemical stratification in flooded underground mines: an overlooked pitfall. Journal of contaminant hydrology 69, 101-114.

Powering Past Coal Alliance: https://poweringpastcoal.org/about/Powering_Past_Coal_Alliance_Members

Younger, P.L. & Adams, R. (1999) Predicting mine water rebound. Technical Report; DOI: 10.13140/2.1.4805.5681

Verhoeven, R. et al. (2014) Minewater 2.0 project in Heerlen the Netherlands: transformation of a geothermal mine water pilot project into a full scale hybrid sustainable energy infrastructure for heating and cooling. Energy Procedia 46, 58-67.